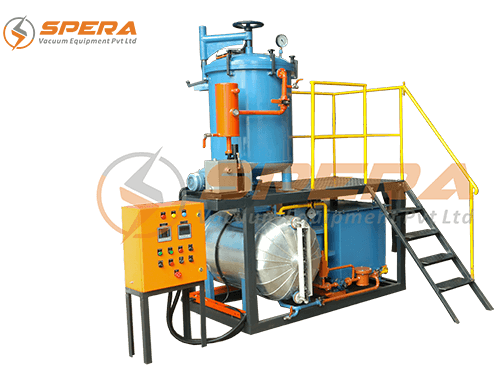

This machine is used for Impregnation of Oil into the Capacitors and Sintered products.

The Components are placed inside the chamber and Vacuumized to draw out the air gaps and then oil is introduced under vacuum so that the oil is easily impregnated into the products.

It consists of Two Storage tank (Raw oil and clean Oil) and Impregnation chamber.

This is for impregnated the oil into the whole clearance of the porous material by capillary phenomenon.

Benefits of Capacitor Impregnation plant:

- Impregnate fluid replaces air pockets in the zinc spray and help in eliminating partial discharges at the end contacts.

- Oil impregnated capacitors have much higher partial discharge voltage as compared to DRY TYPE.

- Heats the sealant which Polymerise the sealant and solidifies within the porosity to prevent the leakage.