This process includes introduction of chemical substances into wood in order to improve its characteristics and impart new properties. Impregnation stabilizes dimensions, increases strength and resistance to water, moisture, and chemicals, and reduces cracking. The most common methods of impregnation employ antiseptics, which ensure protection against wood rot and other forms of biological deterioration, and fire retardants, which prevent wood from catching fire and burning.

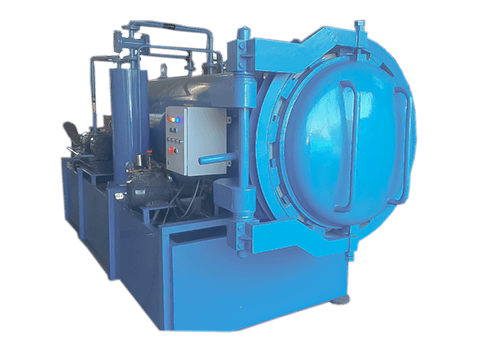

Incorporated with advanced technology, our Impregnation Plants are available for clients in different models to cater their exact needs. Available in horizontal, cylindrical as well as footed models, these plants comprise of mixing tank, impregnation tank, storage tank, vacuum pump and other standard quality components for efficient functioning. The plant is specifically engineered to endow the wood with all the properties it lacks for use in the open air such as longevity, durability and strength.

For this, a variety of preservatives are impregnated into the wood fibers for assuring complete protection against fungus, insects, termites and pests. With these plants, the wood service life can be increased incredibly. Also, we have a variety of options to customize the plants in order to meet client’s exact needs.

Features :

- Easy to operate.

- Corrosion resistance.

- Long functional life.

- Available in different versions.

- Resistance from the outer environment.

- The quality and durability of the product increases after the treatment process